Analytics Strategic Roadmap for Manufacturing Excellence

Client Ask: To create a strategic analytics roadmap for manufacturing excellence, that incorporates existing initiatives.

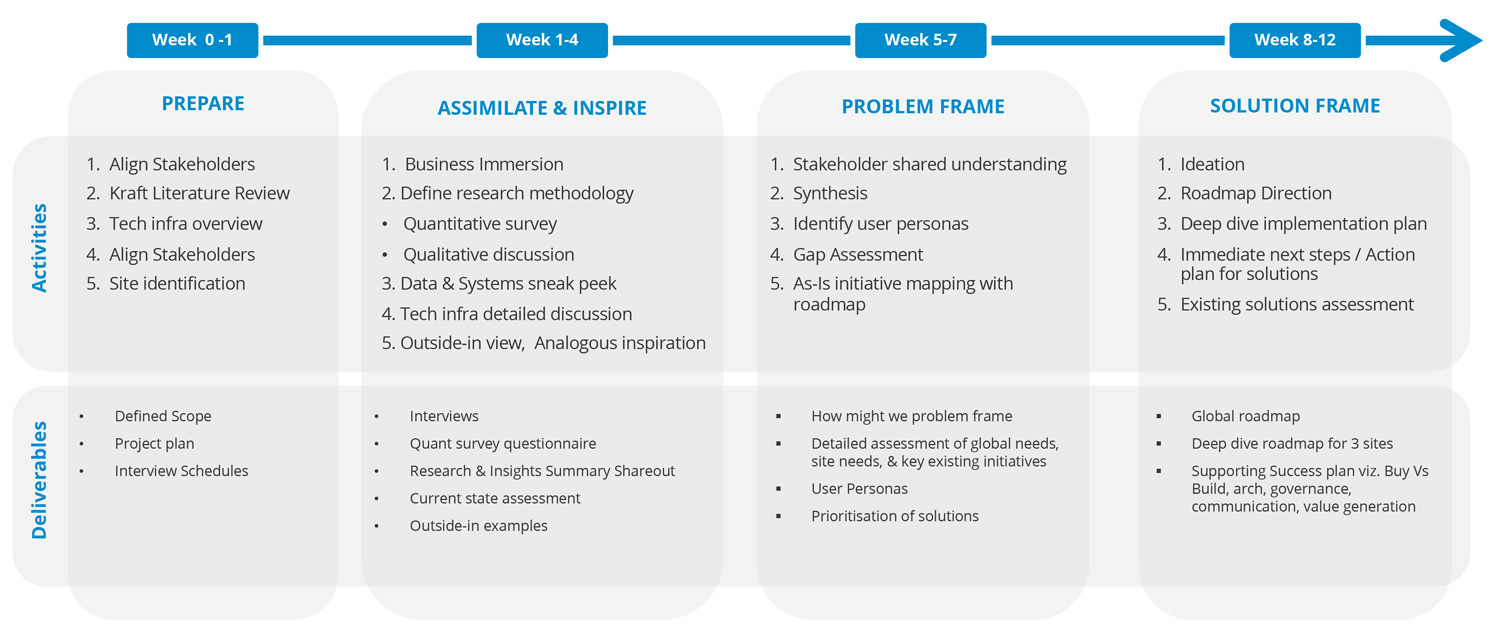

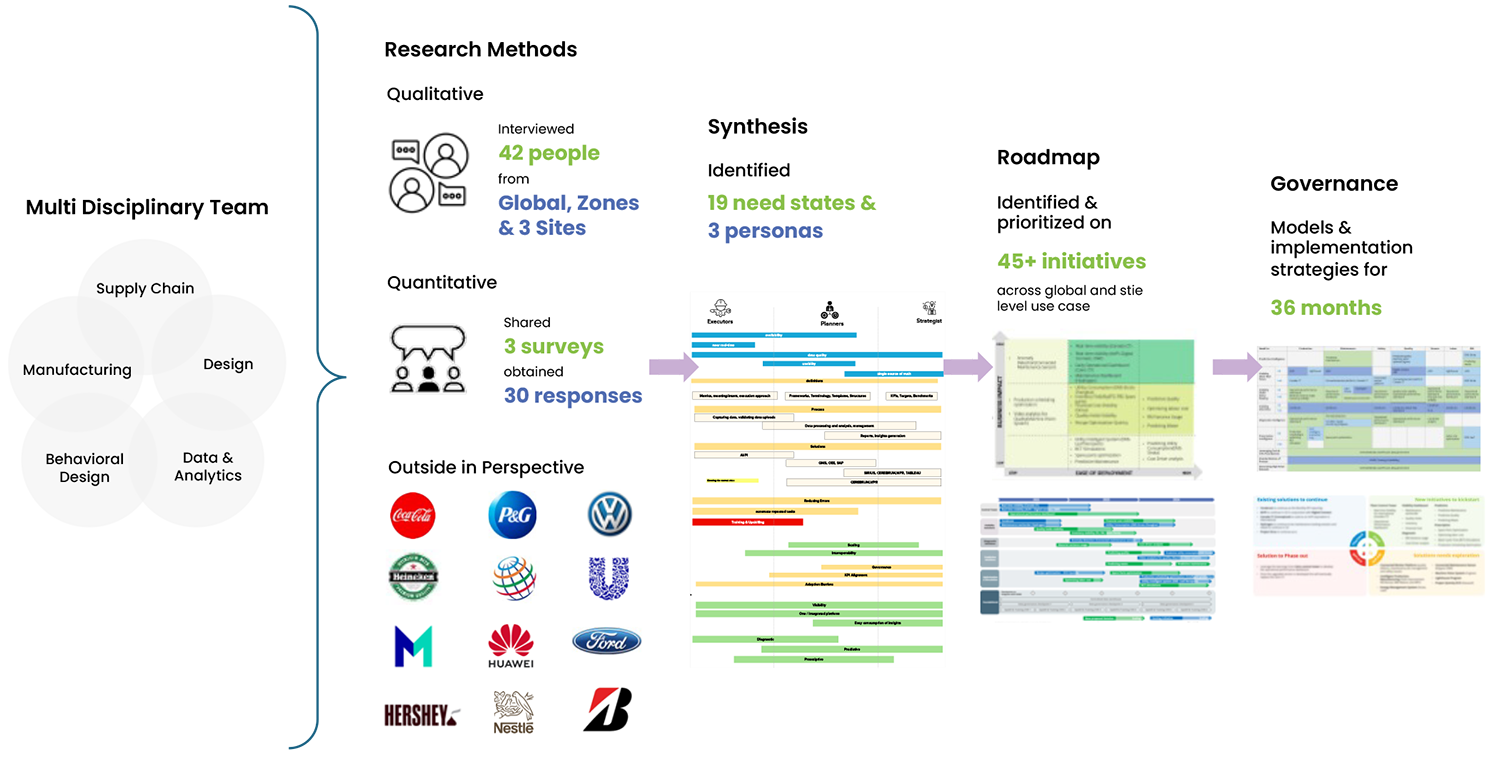

Process: Qualitative Research, Quantitative Research, Outside in perspective, Synthesis, Insights, Ideation, Concept Directions, Feedback and Iteration, Road mapping.

Solution: We gave the clients strategy and recommendations on existing initiatives, new solutions, control tower, data governance, cloud architecture, the vision of manufacturing analytics engine & success plan.

Learnings: Challenge the brief, especially in strategy projects where outcomes are unclear, and periodically reflect on the directions and decisions taken.

Time: 12 weeks

Role: Design Strategist & User Researcher.

Client’s Ask

To create a strategic analytics roadmap for manufacturing excellence, that incorporates existing initiatives. We tried to understand their motivation:

01

The client is looking to create a cohesive company-level analytics strategy.

02

All the sites globally use different systems to manage operations and are not using the full potential of each system.

03

Currently, analytics are driven by multiple teams across different zones and functions in a fragmented system landscape.

04

The clients have invested in multiple solutions, and they need an expert’s view on best ways to utilize them.

05

There is no governance system in place to drive advanced analytics cases within one platform.

Research Plan

Assimilate & Inspire

Qualitative Discussion & Survey

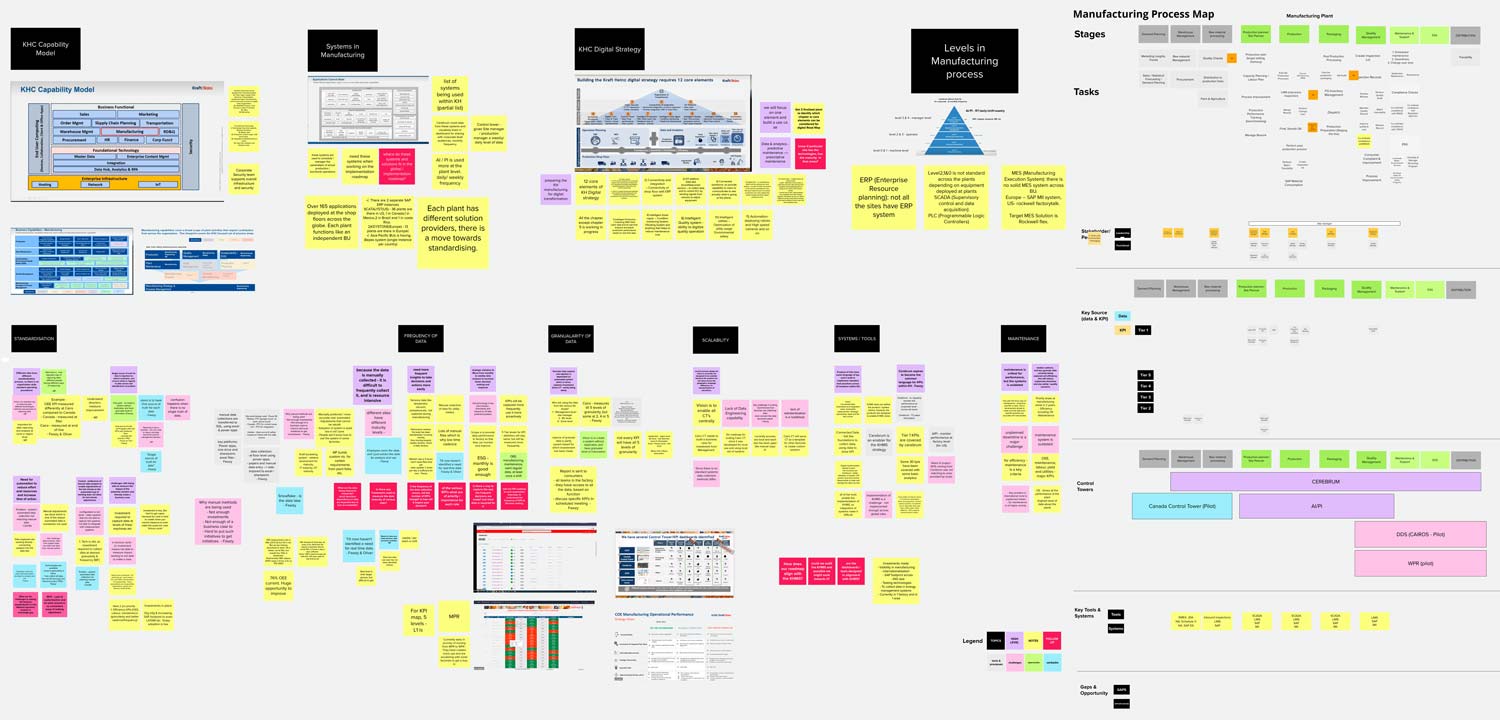

We conducted 30 interviews across global leadership teams to get an overview of the entire manufacturing ecosystem, the digital transformation strategy, levels in the manufacturing process, and their capability model. We also conducted 12 interviews over 3 sites to identify use cases and define an implementation plan for the 3 plants in a bottom-up manner to bring the value of the global analytics roadmap to the shop floor. We also floated 3 surveys and received 30 responses.

What we heard from global leaders during the interviews

~60%

respondents felt that the key challenges in analytics implementation are disparate systems, multiple versions of the truth, and insufficient skillset

67%

see predictive analytics play a big role in the future

78%

say data automation and integration is the 1st step

What we learnt from the surveys

~72%

respondents believe human error, complex & nonstandard KPI definitions are the leading cause of reduced data quality

~61%

respondents believe that currently data is not consumable for insight generation & requires manual intervention

~72%

respondents believe that lack of right skill set, lack of longterm planning & lack of infrastructure are the key barriers to leveraging analytics

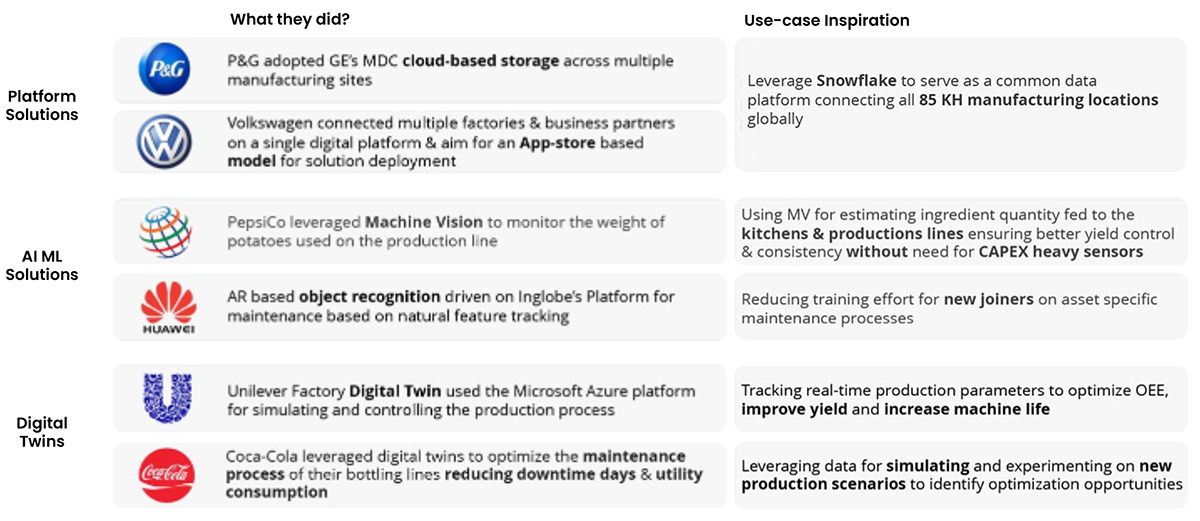

We complemented our research finding with an outside-in perspective

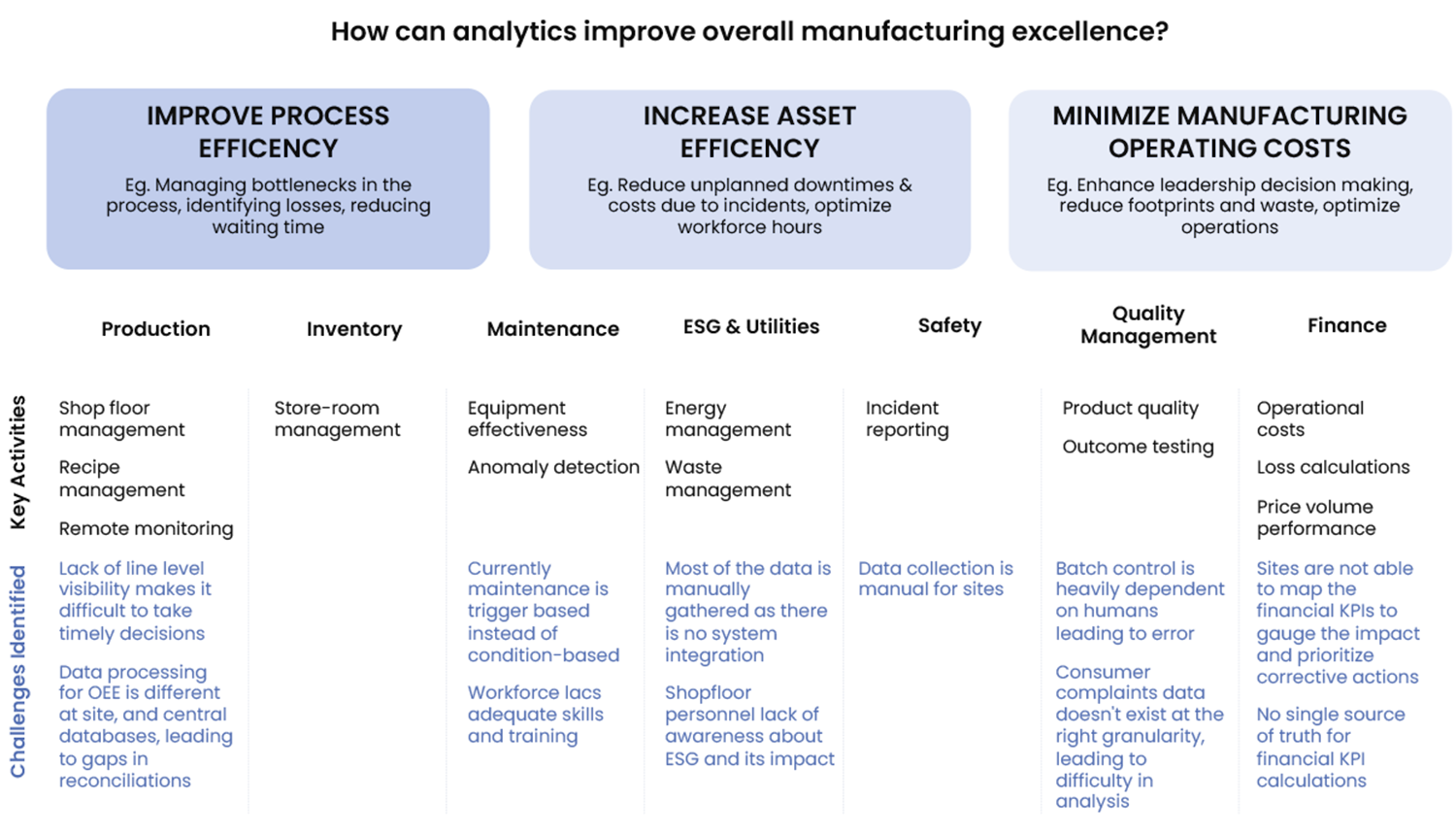

Understanding the Role of Analytics in Manufacturing Excellence

Problem Frame

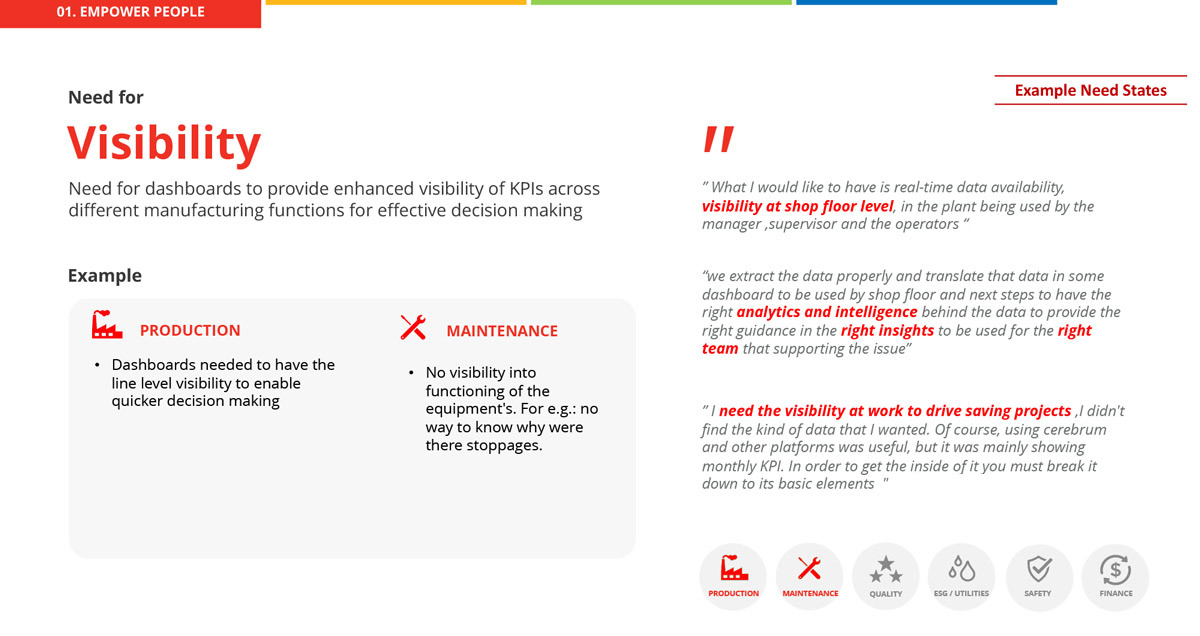

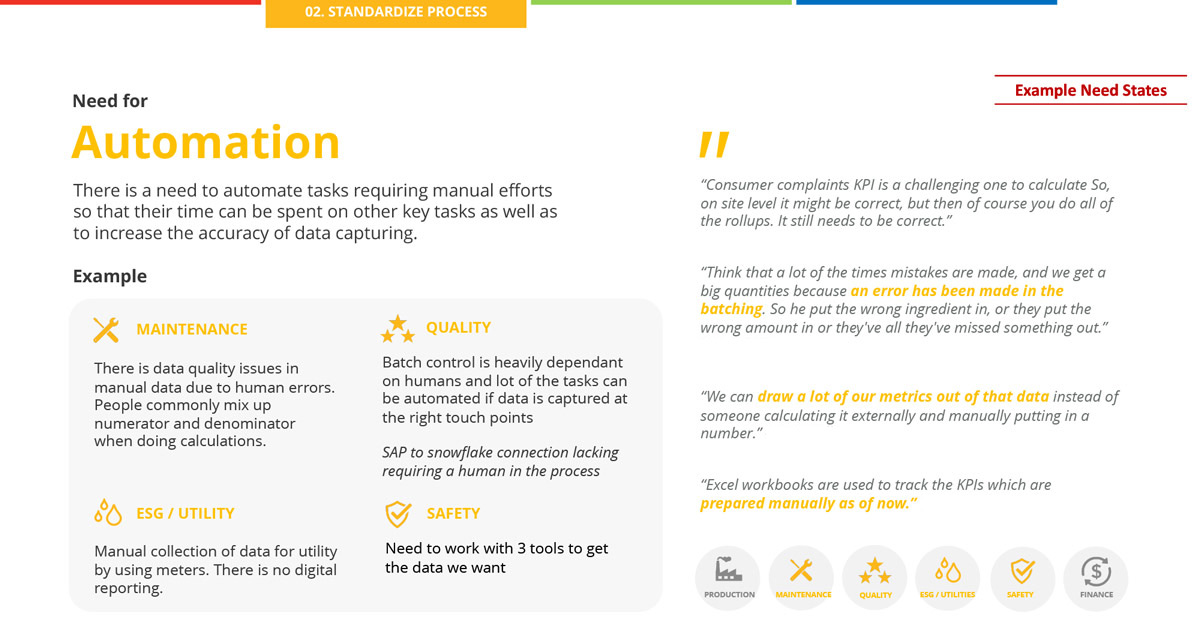

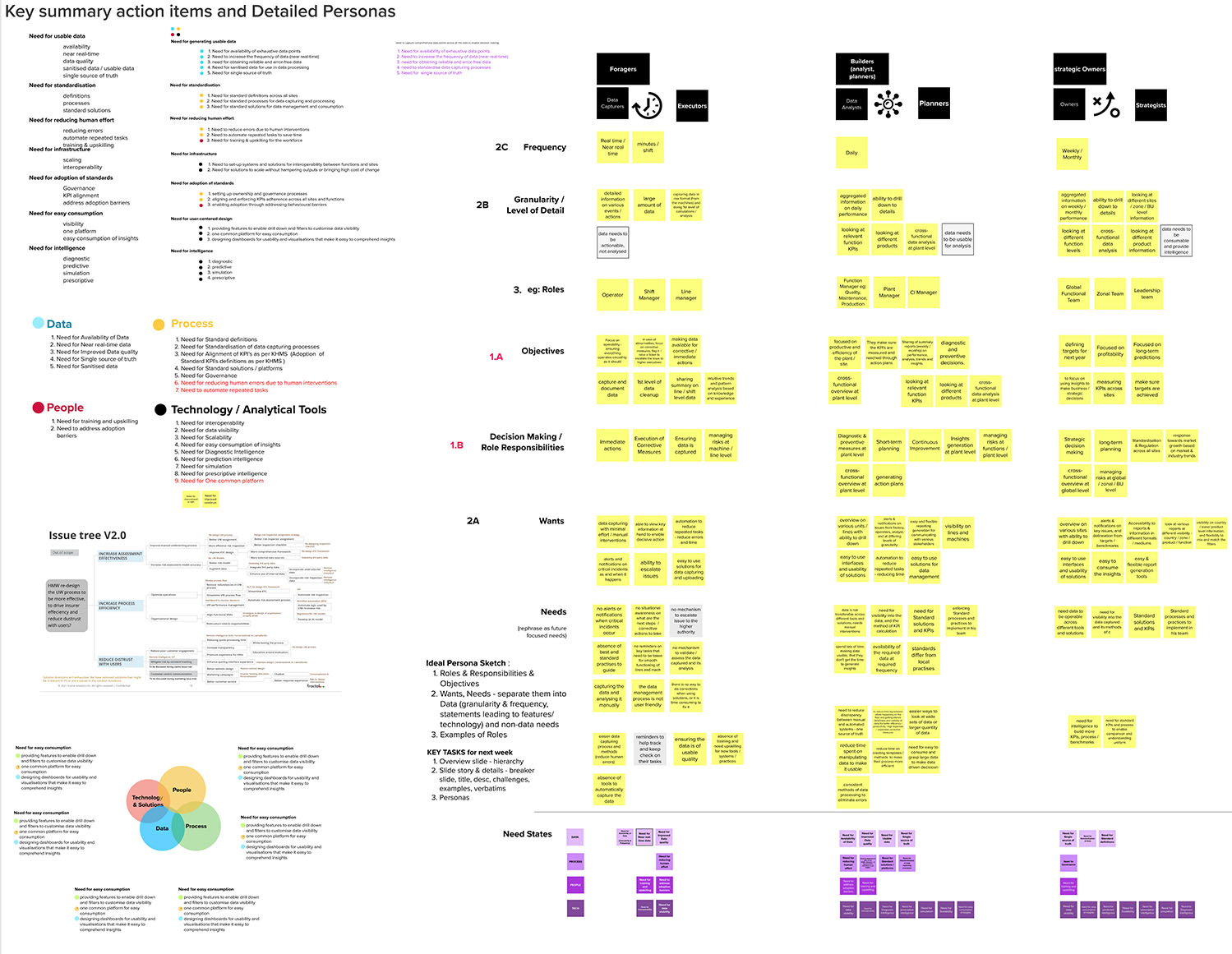

After the research phase, following were key learnings to drive value for Manufacturing Excellence

01

There are 45+ existing initiatives across the Client’s Manufacturing Organisation globally.

- However, the scaled value has not been realized.

- Value derivation can leapfrog with consolidation, focus on adoption, and cloud tech.

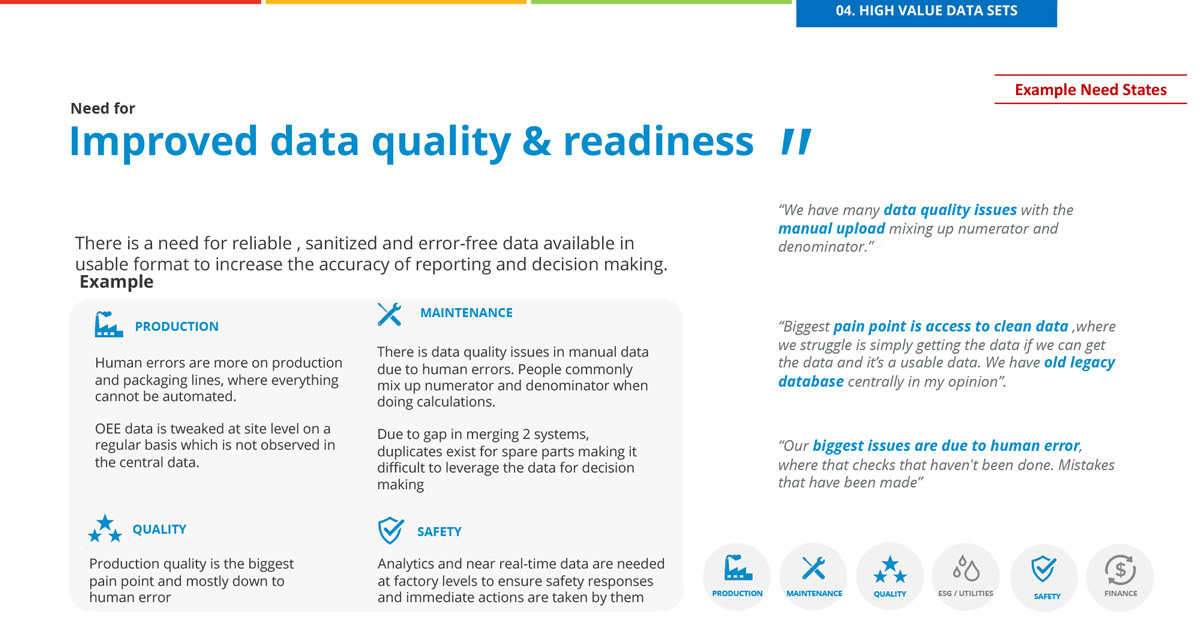

02

Manufacturing vertical needs to create a single source of truth for all, having quality & reliable data

03

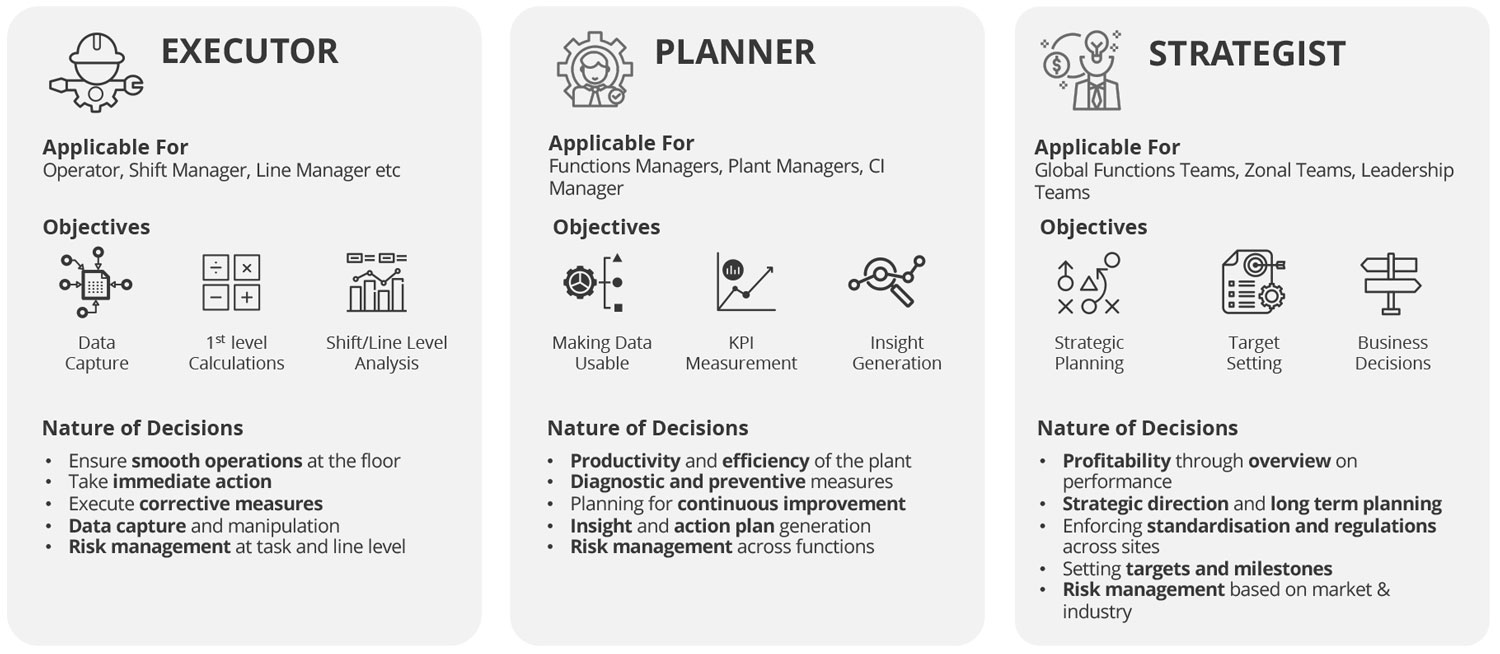

Programmatic value within Manufacturing analytics will be driven by:

- User-persona-driven product features

- Robust data governance

- Enhanced processes (through KHMS)

- Embedding augmented intelligence

- Hand-holding during hyper-care phase

04

$500Mn+ potential savings realised by implementing some of the best-in-class analytical solutions like predictive quality, predictive maintenance, spare parts optimization, etc.

7% – 11%

improvement in asset utilization through predictive maintenance

10%

improvement in product off spec management through predictive quality

5%

reduction through improved demand forecasting accuracy and inventory optimization of spare parts

15%

reduction in capex through long-term capacity planning

Solution Frame

How Might We empower manufacturing to leverage data – driven decisions for achieving process excellence, reducing costs, and increasing productivity?

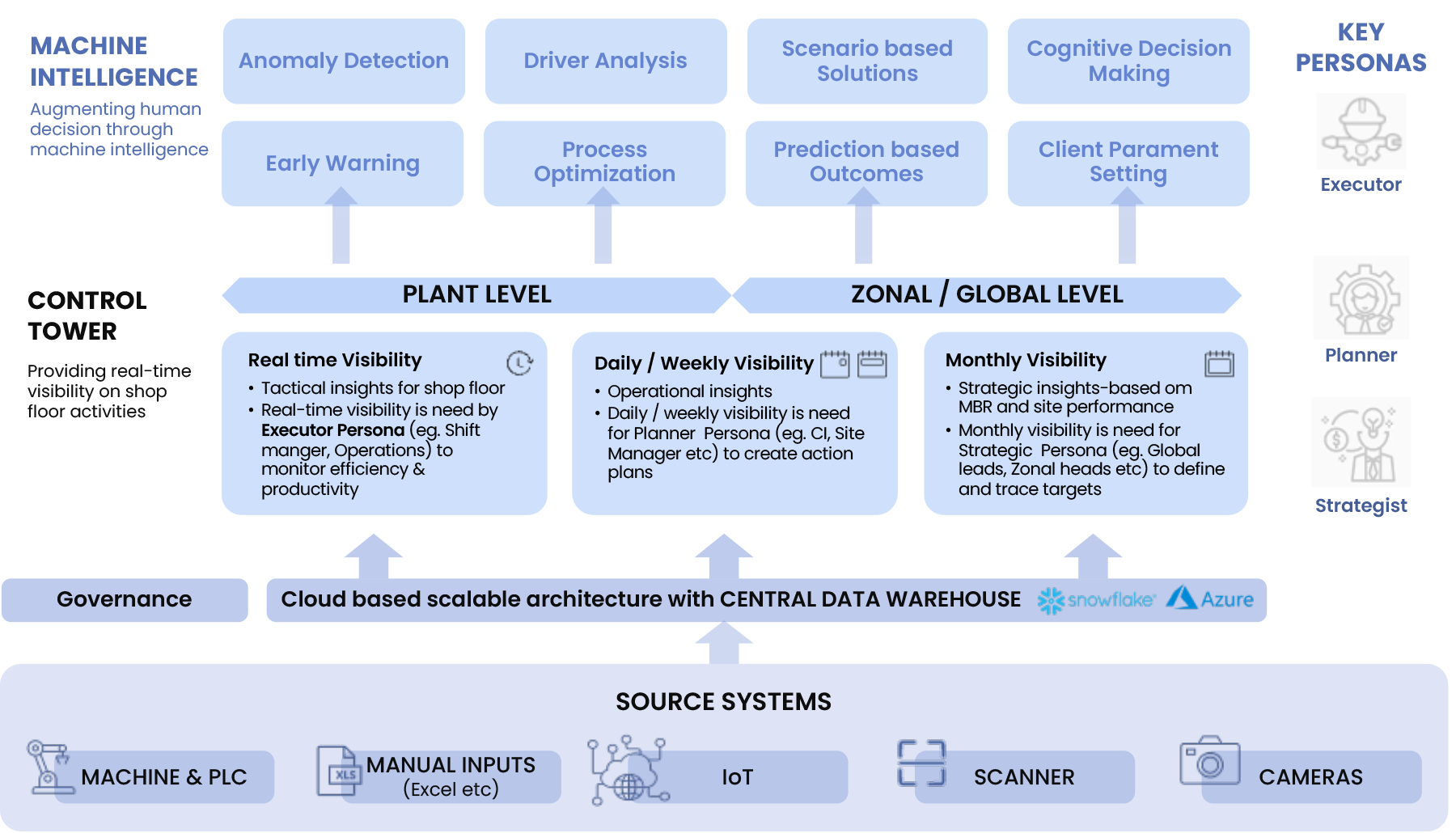

Demystifying a Control Tower

Air traffic control towers are critical to the functioning of airports, and they do this by coordinating takeoffs, landing, ground traffic, and aircrafts in flight within a range of 5 miles of the airport.

Understanding what is a Control Tower?

A control tower is an elevated entity in the architecture that provides an unobstructed view into all key information required to control and make decisions on the various operations of the manufacturing

Why do you need a Control Tower?

A control tower enables organizations to connect events across manufacturing with key business metrics to improve and accelerate decision-making, resolve risks and prioritize outcomes in real-time.

Success criteria: A PoV on an ideal control tower

The Vision

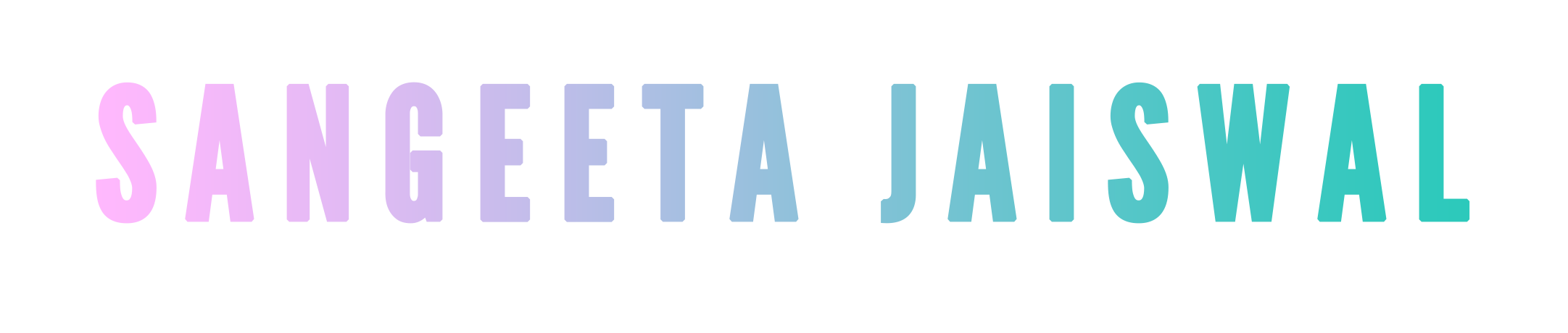

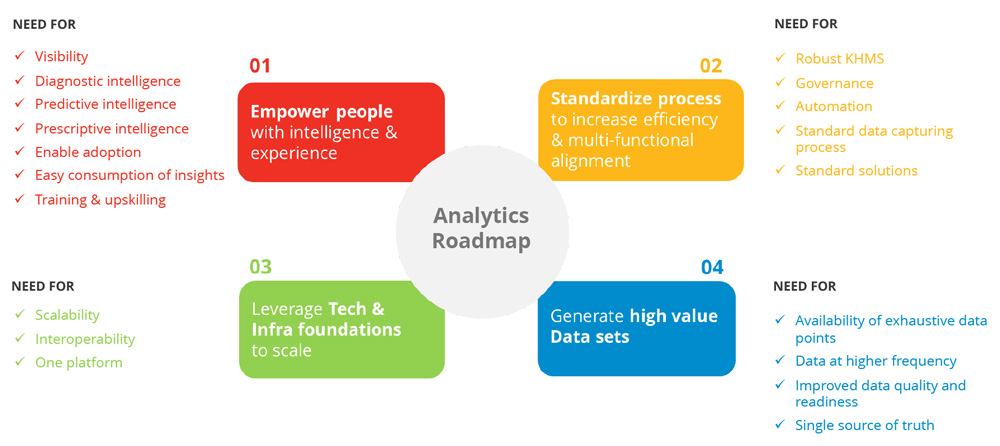

Holistic 4-pronged solution framework to digitize the manufacturing decisions

01

Leveraging existing solutions

- Exploring existing initiatives to map with need states

- Enhancing and scaling the solutions

- Assess the life cycle of solution to recommend next steps

02

Developing analytics solutions

- Identifying the new analytical solutions in form of visibility, predictive, and diagnostics as per need states

- Recommending must-have functionality and features in visibility solutions

03

Setting up architecture for scale

- Setting up a global architecture to support analytical needs

- Leveraging existing cloud infrastructure to build a scalable and robust platform

- Setting up governance structure and team

04

Driving adoption strategies

- Identifying training needs and upskilling resources

- Creating an adoption framework for success

- Assessing the change management activities to support and enable a smooth transition

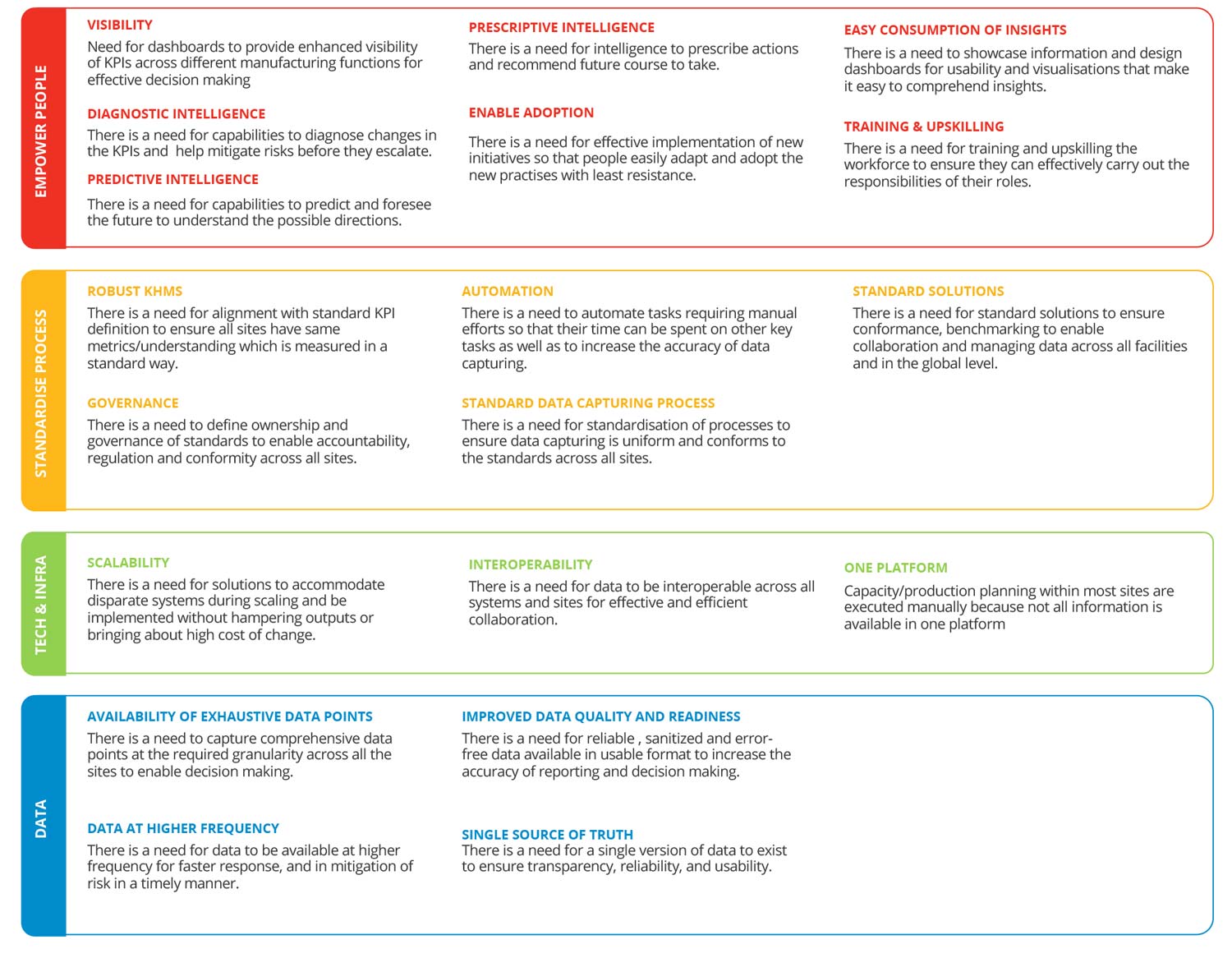

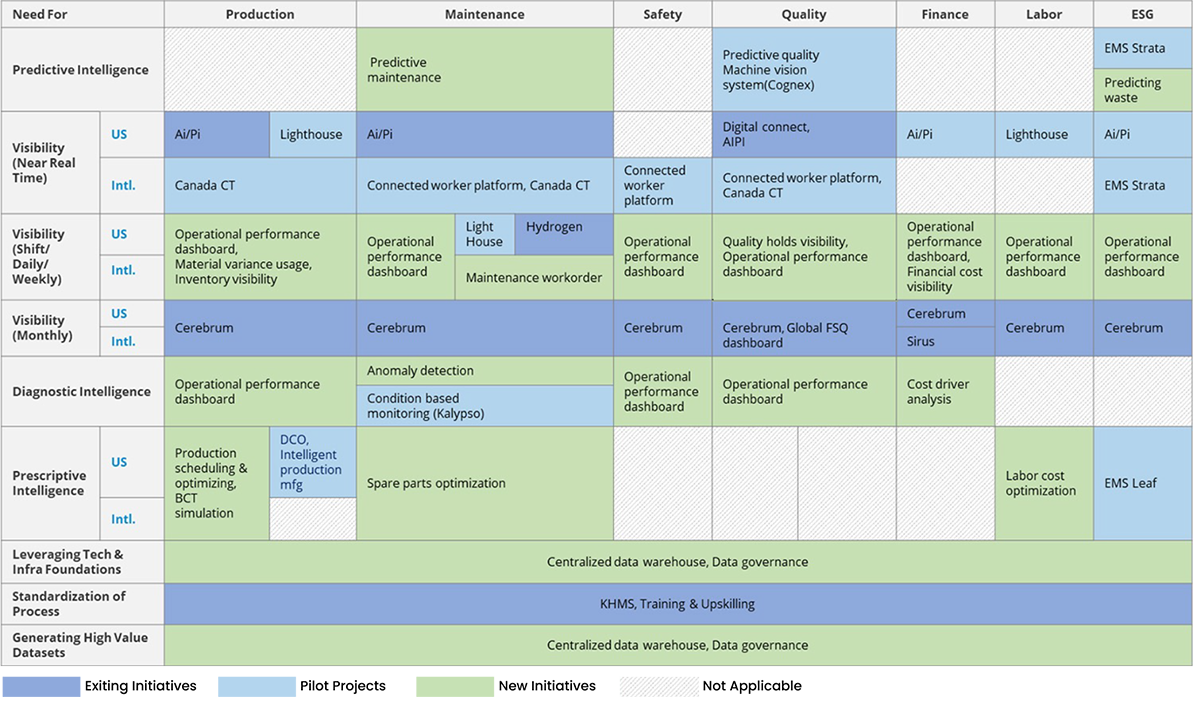

When the existing initiatives are complemented with new solutions, all needs states stand addressed

35%

need states are addressed partially through existing initiates – Require enhancements & integrations

65%

need states are unaddressed – Require new analytics solutions to solve

25%

of total needs are classifies as foundational while the rest are analytical needs driven

45%

needs can be address through setting up a strong data foundation layer, developing a control tower and maintaining one solution

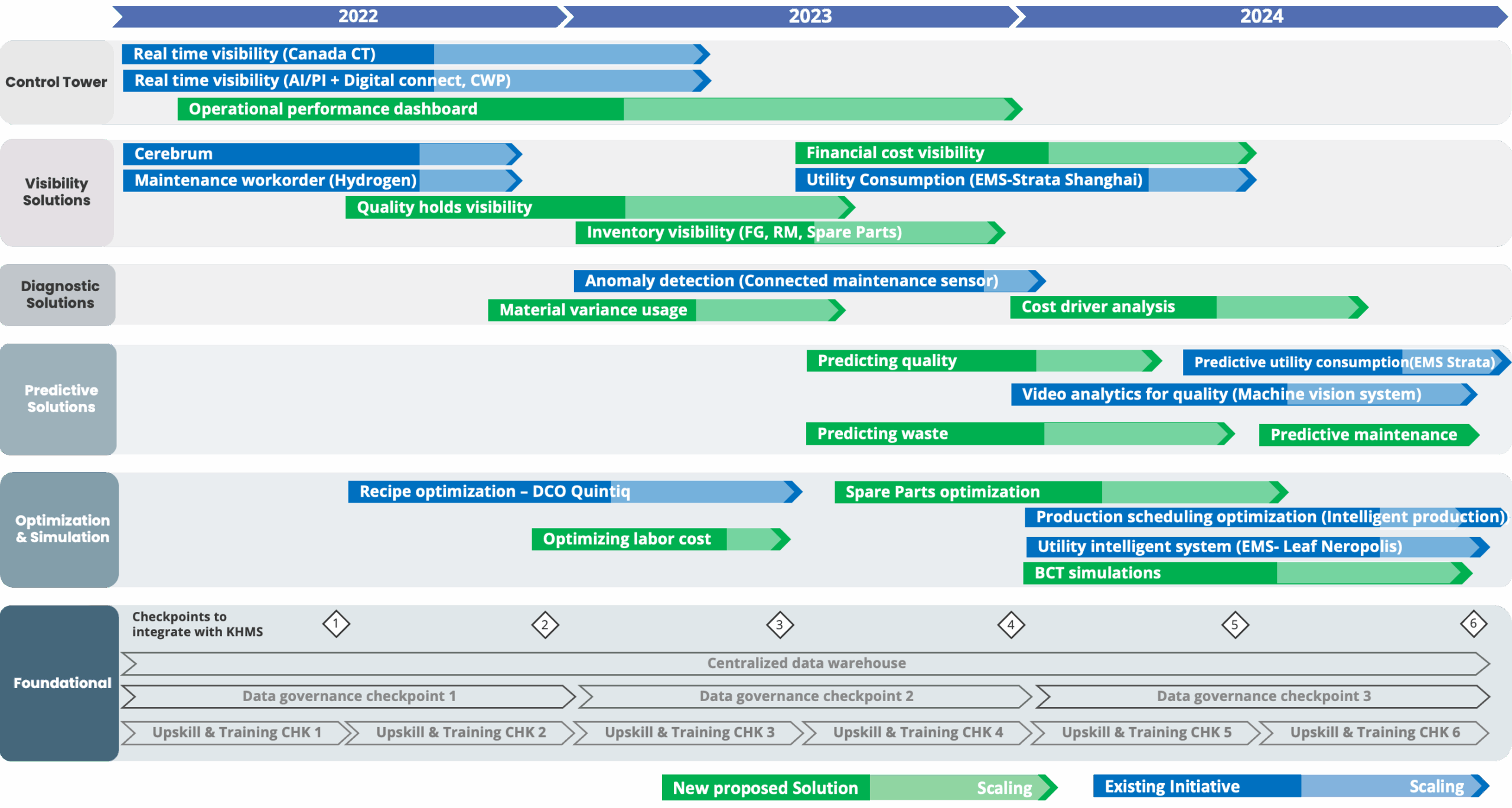

Recommended Global Roadmap

Out of key 14 existing solutions

6 to continue, 7 to be explored, while 1 needs to be phased out

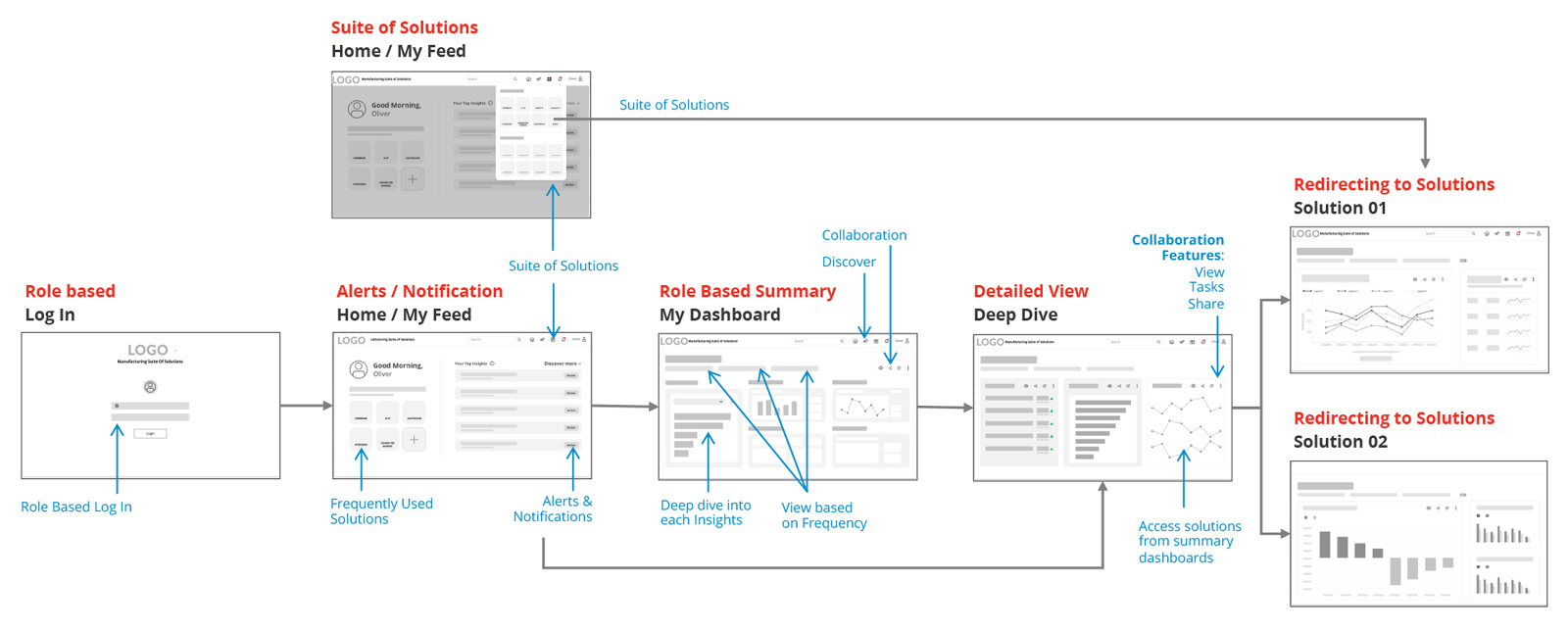

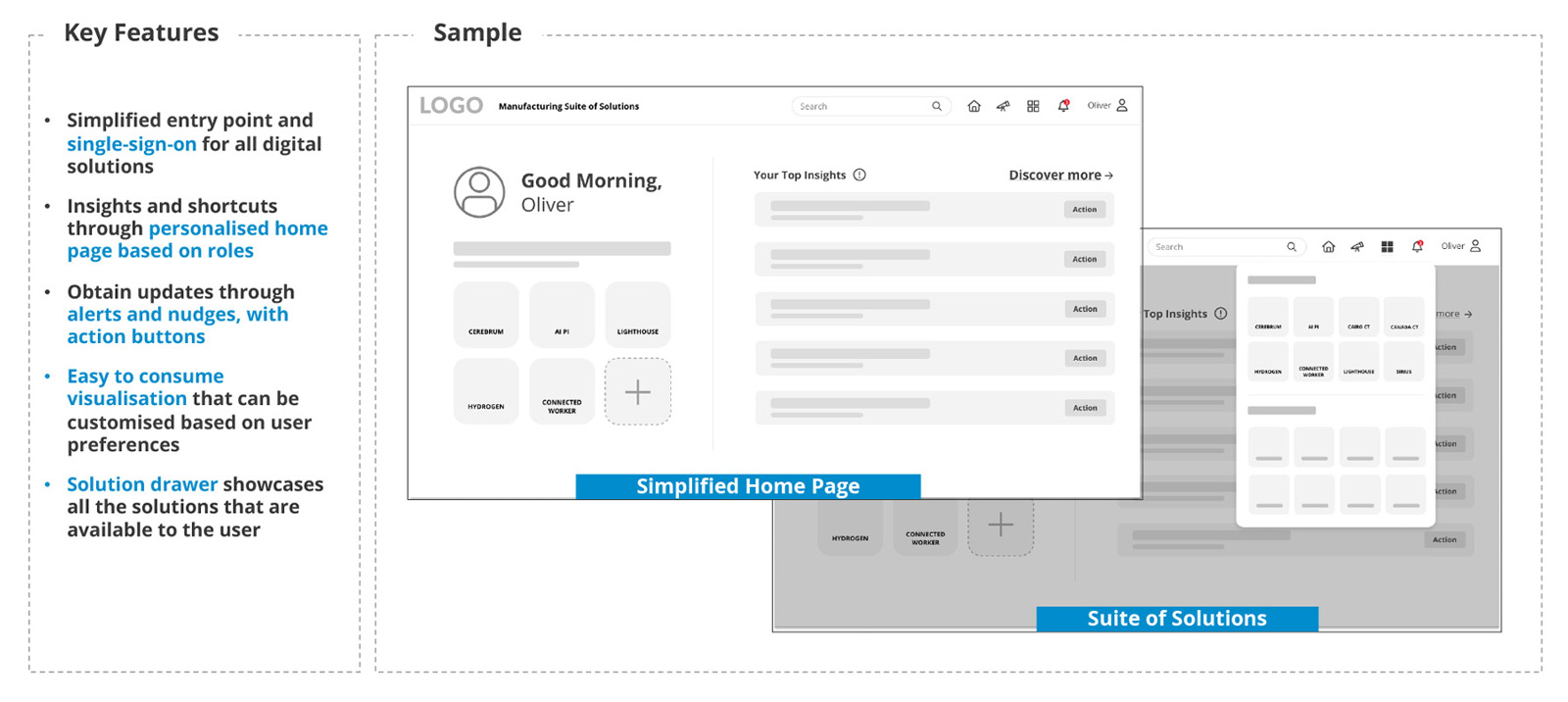

User Experience

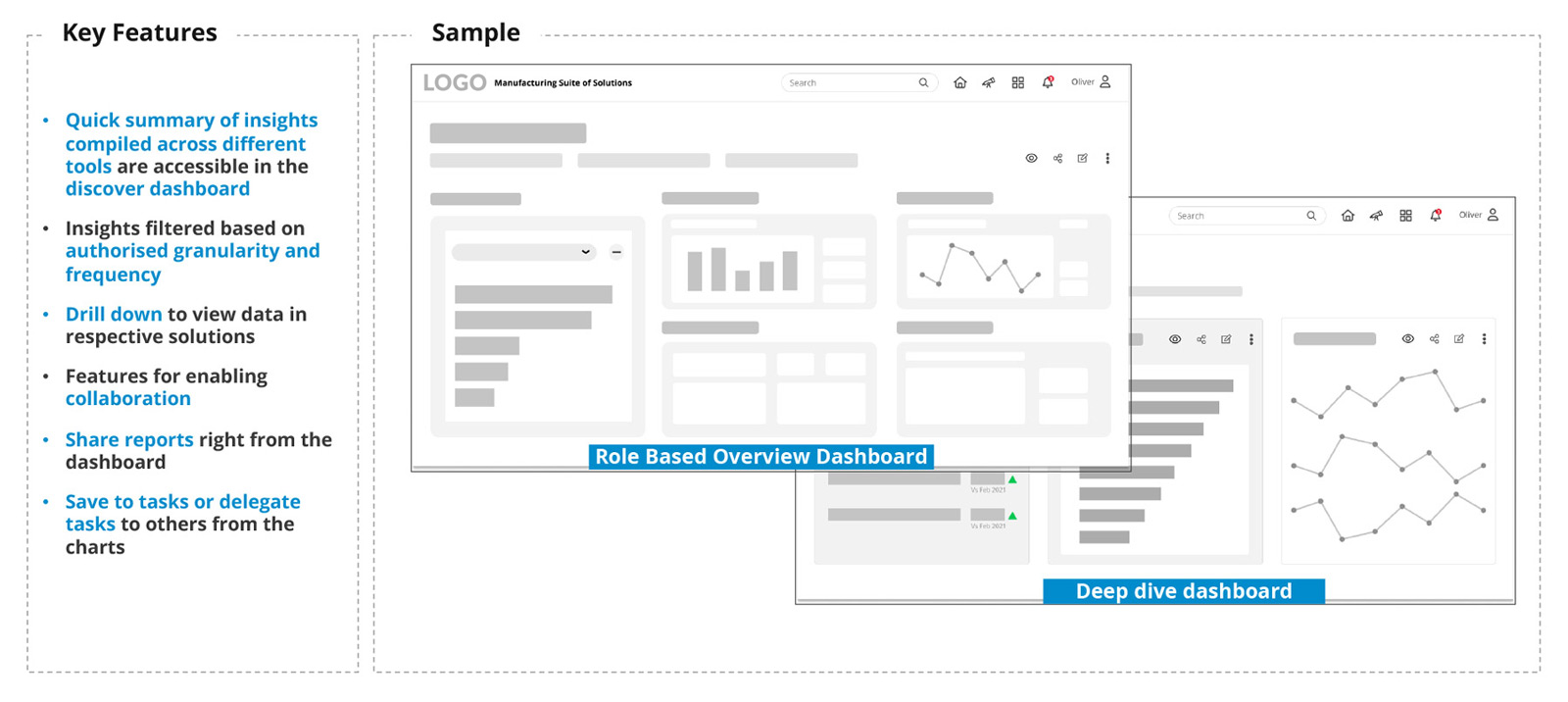

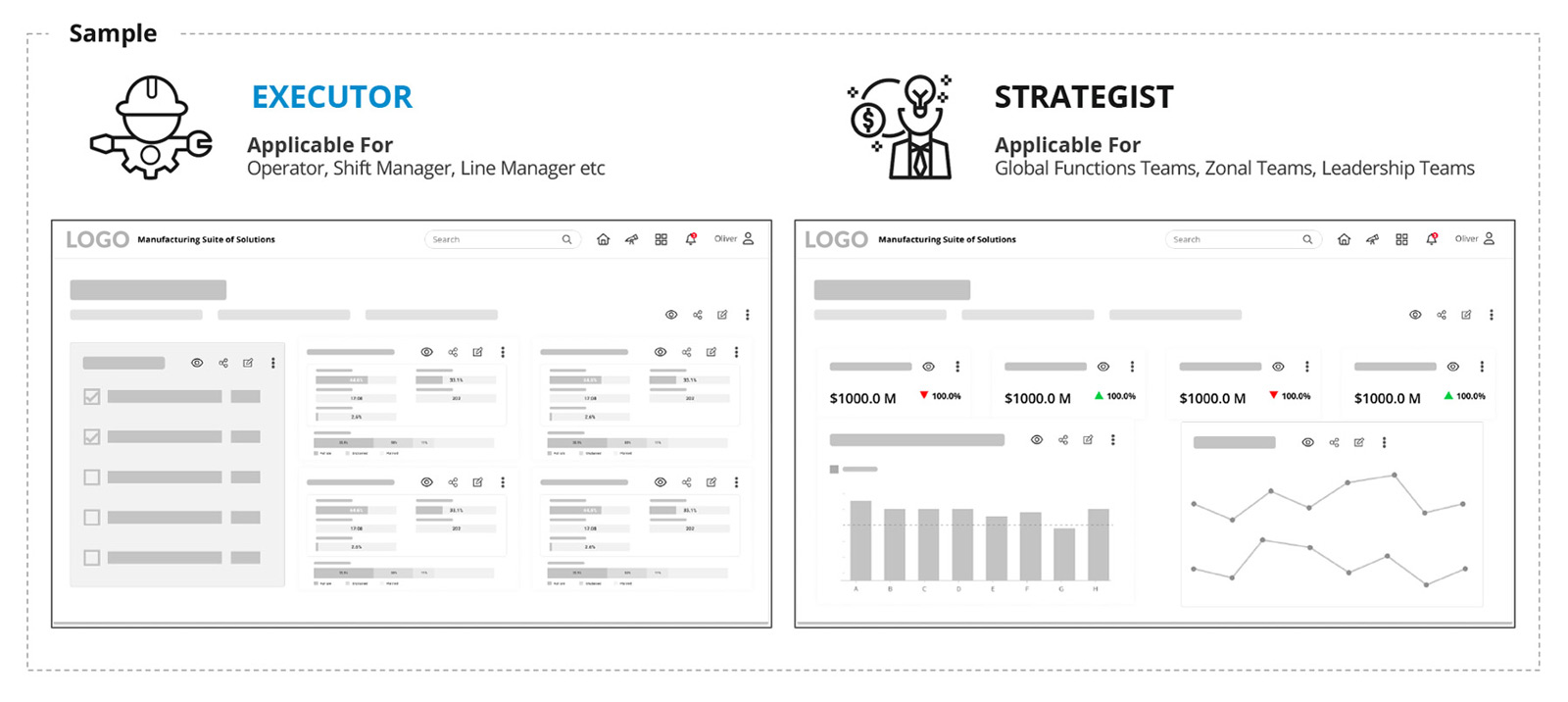

Key Features

Value Created

Challenging the status quo

- Set the analytics best practices set for the client

- Innovation or enhancements

Decision Enablement

- Decisions being taken due to the initiative which were not taken before

- Data foundation / Frameworks built to integrate sources

Speed of Insights

- Reduced data to report creation time

- Reduced overall data to decisions time

Cost Savings

- Decommissioned periodic reports created by Kraft-Heinz Associates or vendors

- Time to integrate data sources, or generate insights, rework due to follow-ups

Revenue Increase

- Direct revenue increase by decisions suggested

- Indirect revenue increase by decisions suggested

Reflection:

Set the expectations right from the beginning and manage it throughout the project to avoid scope creep and last-minute changes.

Challenge the brief, especially in strategy projects where outcomes are unclear, and periodically reflect on the directions and decisions taken.

Drive a pilot phase and produce tangible results to provide proof of value for our recommendations and increase our credibility and foster longer client relationships.